At the edge of the sand field, a crane truck is waiting to start work next to a precast concrete factory. A group of people are busy nearby, wearing protective gear. The base slab, weighing almost six tons, is already in place, but it is clear from everything that this is not a normal construction site.

In the training organized by Rateko at Lujabeton's Järvenpää factory, the element installation exercise for vocational school teachers is about to begin. All arrangements have been made as if it were a real concrete element installation job on a construction site. A lot of adjustments were made the previous day, and the company that supplied the lifting equipment also visited the site four times to correct any deficiencies. Everything in the training must be in order – as it should be on construction sites.

Think and don't remember.

“An unfinished hollow core slab field is always dangerous,” begins Hartela’s precast concrete construction expert who led the exercise. Sami Lower Pieti"When dismantling a precast concrete block, it is important to take the installation order into account. The hollow core slabs must also be loaded in the correct order," he continues.

The aim is to assemble four side wall elements, end walls and two hollow core slabs on top of the base slab. The elements are lifted into place in a slightly different order than what was seen in the papers the previous day. However, this does not affect safety, says Hartela's experienced measurer who served as the second trainer. Esa Rouvali.

The elements must be dismantled from the frame in order from the sides towards the center. The structure also has a scaffold from which you can climb up to the vault safely. To ensure this, the gallows were attached to the scaffold first, as were the railings.

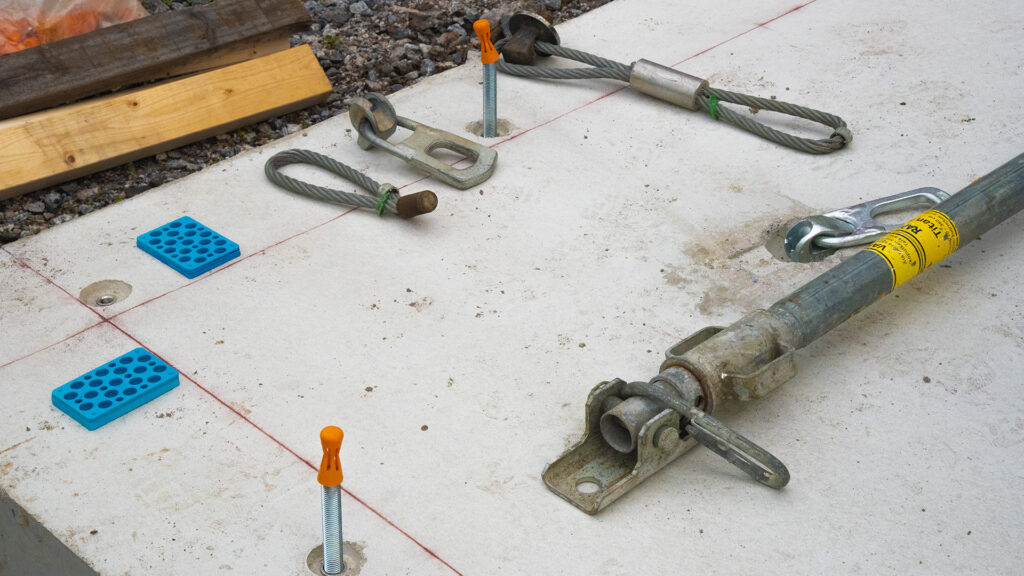

Right from the start of assembly, challenges arise that are solved together. One discussion arises about the leveling plate used for lifting, which is often found in element installation plans, but rarely on construction sites.

"Instead of thinking that we will do it as it has always been done before, the installation team should consider what is the right way to perform the lifting in question. For example, using a safety-enhancing leveling plate will not interfere with or slow down the installation in any way," emphasizes Sami Ala-Pieti.

Differences in lifting aids

Next comes the lifting lock, the advantages of which Sami Ala-Pietilä praises, whether it is a case of lifting a solid slab or a balcony slab. It can be used to ensure that the element is lifted safely and there is no risk caused by the threads.

"Balcony tiles are also about aesthetics, as the customer does not always appreciate the fact that a large hole is left in the tile after the lifting pin. However, it is a minor inconvenience as long as the lifting is done safely. However, the hole is patched and cleaned up at the end, similarly to the screw anchor."

When the first wall element was lowered onto the base slab in the Järvenpää training, the crane driver first left it “loose”, meaning that almost all of its weight was still on the hook, so that the installer could fine-tune the element to the correct position with a crowbar if necessary. Only when everything is in order and the pushers are in place is all the weight lowered down.

“It is very important not to adjust the element once the hooks have already been removed. Although the trick to installing elements is how fast the crane moves, safety must always come first,” Sami Ala-Pieti reminds. There have also been serious accidents in Finland recently, the cause of which has been precisely the fact that elements have been adjusted even though the hooks have been removed.

Human errors highlighted

There are many dangerous places to make mistakes when installing elements. Normal stones easily weigh five to six tons and sometimes well over 10 tons. Human errors are the biggest risk factor in lifting, technical factors such as the durability of lifting links or pulls are rarely the cause of dangerous situations.

"If the lifting anchor is left crooked and the stone is lifted or, in the worst case, the situation is corrected by chiseling, it is a human error. You should never chisel the drawbars and lifting elements, but in that case you should always contact the designer. Similarly, if they have already been chiseled at the element factory, you should not start installation on the construction site," Ala-Pieti advises.

Rateko's element installation and safety training for teachers at vocational schools received a lot of praise. One of the people who praised it was a tutor for the basic construction qualification at Varia Vocational School. Jari Tyni.

"I also joined the training out of my own interest, because I'm not very familiar with precast installation. I've gained a lot of knowledge here about how precast construction is done today, and we can now pass that knowledge on to the students. Many students also work at the same time, and get to learn about precast concrete construction in the workplace."

Jari Tyn thinks it would be great if schools could also practice with the right equipment, like in Rateko's training. "By participating in the practical assembly of elements in this way, you learn things so much better. At the very least, element construction should now have its own section in the school's online theory subjects," he says.

"The topic will continue to be discussed in the spring in a webinar organized by Rateko on April 10.4.2025, XNUMX, where everyone involved in teaching in the construction industry is welcome to hear more about training in the installation of concrete elements," advises Rateko's training expert. Jukka Isomöttönen.

The aim of the training at the Construction Industry Training Centre Rateko was to increase the competence of construction industry educators in teaching safe working at height and concrete element installation. The project utilised top expertise in the field, ensuring both the safety of the training situation and a high-quality teaching situation. The training, which promotes construction industry competence, was organised as part of the Competent Vocational Teacher project funded by OPH.

Sweco was responsible for the structural design of the elements. The elements were designed taking into account that they would be used for educational purposes. Reinstallation and repeated dismantling, among other things, differed from normal in terms of material choices, strength, and the number of lifting parts.

The elements were manufactured at Lujabeton's Järvenpää factory, whose element field also offered good facilities for training. A tour of the factory, which was part of the training, also sparked enthusiastic discussion among the teachers.

Support and other equipment for the training was found from Ramirent, and Kallioinen Cranes was responsible for the lifting work. The crane operator who worked in the training Laura Pessi gave the trainees good tips on the safety of lifting work from the driver's perspective. When going through other safety issues, the expertise of Tapaturva Oy was relied on.

Hartela provided technical support for the project, organized a professional installation team on site, and was also responsible for giving lectures on prefabricated construction.